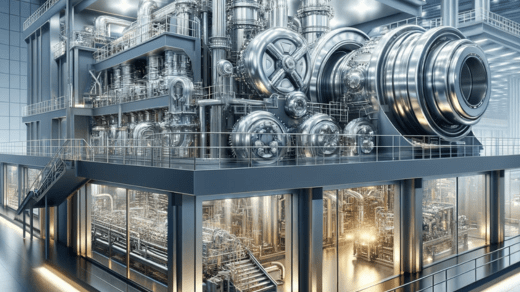

precious metal refiners UK

Precious metal refining is a meticulous process aimed at separating noble metals, such as gold and silver, from non-noble metalliferous materials. Among the common procedures employed, pyrolysis and hydrolysis stand out, each with its unique approach to isolating these valuable materials.

For those contemplating the recovery of precious metals from scrap, seeking professional assistance from reputable precious metal refiners UK is strongly advised. However, it’s highly essential to understand a set of crucial do’s and don’ts before working with a precious metal refiner.

Do’s of Working with a Precious Metal Refiner

Keep the following pointers in mind while working with a precious metal recovery companies:

1. Provide Comprehensive Information

Furnish your refiner with detailed information about your scrap. The composition of your materials guides the refiner in choosing the most appropriate recovery process, directly influencing the accuracy of the return value.

2. Visit the Refinery

Transparency is key. Request a visit to the refinery facilities, including the laboratory where materials are analyzed. Understanding the processes firsthand and whether the refiner operates in-house or acts as a broker enhances trust in the partnership.

3. Understand the Analysis Process

Familiarize yourself with the methods employed for sample analysis. The level of accuracy in the analysis directly impacts the quantity of gold or silver that can be recovered from your scrap. Ensure the lab is equipped with up-to-date techniques.

4. Evaluate Refiner Experience

Confidence in the refiner’s ability to handle your material is crucial. Verify the training and skills of the refiner, ensuring they have the expertise needed for proper material handling.

5. Check Regulatory Compliance

Ensure the refiner complies with all current regulations and verify if they are fully licensed with the Environment Agency. Responsibility in waste disposal is ethical and a legal obligation to prevent future liabilities for all precious metal recovery companies.

6. Prepare Scrap for Collection

Eliminate extraneous materials from your scrap before collection. This saves time and money, ensuring the refiner picks up only what is worth refining. Consult with your refiner to implement best-practice guidelines.

7. Evaluate Refiner Terms

Ensure the refiner’s terms align with your business needs. Whether your priority is the highest quality return, flexible return options, market flexibility, or local proximity, finding a partner that meets your needs reduces stress in managing your business.

Don’ts of Working with a Precious Metal Refiner

Just like there are various do’s while working with precious metal refiners UK, there are also some things you must refrain from. These don’ts are as follows:

1. Don’t Mix Precious Metals Unnecessarily

Refiners often have minimum percentage requirements for efficient processing. Separate your scrap by metal type to receive better settlements, ensuring optimal returns for each metal.

2. Don’t Choose Based Solely on Location

Avoid selecting a refiner solely based on proximity. Request quotes from 2–3 businesses, evaluate costs versus benefits, and consider the most cost-effective service, even if it requires a bit more travel.

3. Don’t Delay Refining Due to Price Fluctuations

Refining should not be delayed based on predictions of precious metal price increases. Trust the best quote from your chosen partner and proceed with refining. Selling the pure product is generally more profitable than holding onto unknown scrap.

4. Don’t Be Overjoyed by Unexpectedly Large Returns

Unexpectedly large returns may indicate inefficient processes, leading to excessive waste. Collaborate with your precious metal refiner to minimize wastage and improve overall efficiency.

Conclusion

Working with precious metal refiners UK requires a balanced blend of knowledge, transparency, and collaboration. Whether you are an investor, jeweler, or part of an industrial operation, adhering to these do’s and don’ts ensures a mutually beneficial relationship with a reputable precious metal recovery company.