Control integrators

Automation continues to evolve at a rapid pace, driven by technological advancements and the need for efficiency across industries. Control integrators are at the forefront of this transformation, adapting and incorporating new trends that shape the future of automated systems. Whether it’s improving data sharing or enhancing human-robot interaction, control integrators are focusing on several key trends that will make automation smarter, faster, and more adaptable.

Increasing Reliance on Industrial Internet of Things (IIoT) for Real-Time Data Sharing

The Industrial Internet of Things (IIoT) is revolutionizing how data is collected and shared in industrial environments. More than just a buzzword, IIoT allows devices, machines, and sensors to communicate with each other in real-time, offering unprecedented access to operational data. This is a game-changer for control integrators who can now design systems that provide instant feedback and diagnostics.

By incorporating IIoT, control integrators enable businesses to monitor production processes in real time, making it easier to spot inefficiencies or equipment malfunctions. This helps minimize downtime and allows for more informed decision-making. The ability to have all systems talking to one another also means that the control integration process becomes more seamless, as data can flow smoothly across various platforms.

Furthermore, the integration of IIoT supports predictive maintenance, which is a growing priority for industries looking to reduce unexpected breakdowns. By analyzing data patterns, control integrators can design automation systems that predict when a machine will likely fail, allowing for repairs before any significant issues occur. This trend is helping businesses save on maintenance costs and reduce overall production disruptions.

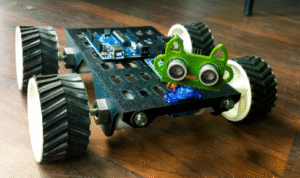

Utilizing Collaborative Robotics (Cobots) for Human-Robot Cooperation

Collaborative robots, or cobots, are gaining traction as more industries recognize the benefits of human-robot teamwork. Unlike traditional robots, which often require segregation from human workers for safety reasons, cobots are designed to work alongside people. Control integrators are increasingly incorporating these robots into their designs to enhance productivity and safety.

Cobots are particularly useful in tasks that require precision or repetition, allowing human workers to focus on more complex activities. By integrating cobots, control integrators are helping industries reduce labor costs while improving accuracy in various manufacturing processes. This collaboration between humans and machines opens up new possibilities for automation, where robots can assist rather than replace human workers.

Incorporating cobots into automation systems also allows for greater flexibility. Control integrators design these systems so that they can be easily reprogrammed or adapted to handle different tasks, making them ideal for industries where production lines frequently change. The ability to integrate cobots is transforming workplaces by combining human creativity with robotic efficiency.

Deploying Advanced Sensors for More Accurate Data Collection and Analysis

Sensors are the backbone of any automated system, and recent advancements in sensor technology are allowing control integrators to gather more accurate and detailed data than ever before. These sensors are now more precise, robust, and able to operate in harsh conditions, which makes them critical in industries like manufacturing, agriculture, and logistics.

Control integrators are leveraging these advanced sensors to improve system reliability and data quality. For example, sensors can now monitor everything from temperature and pressure to motion and proximity with a high degree of accuracy. This level of detail enables better automation control, ensuring that processes run smoothly and products meet quality standards.

What’s more, advanced sensors allow for real-time data analysis, providing businesses with immediate insights into their operations. This rapid feedback loop is essential for optimizing efficiency, as it allows for instant adjustments to be made in the automation process. Control integration that utilizes cutting-edge sensor technology gives companies a competitive edge by delivering faster, more reliable performance.

Focusing on Modular Automation Systems for Flexible Manufacturing Environments

As manufacturing environments become more complex and varied, the need for flexibility in automation has never been greater. Control integrators are increasingly focused on developing modular automation systems that can be quickly adapted or reconfigured as production needs change. These systems consist of interchangeable modules that can be customized or replaced without overhauling the entire automation infrastructure.

Modular systems offer a high level of flexibility, which is particularly valuable for industries that require frequent shifts in production lines or product designs. Control integrators design these systems to be scalable, allowing companies to expand or modify their automation setups as needed without significant downtime or cost. This modular approach is reshaping how businesses think about automation, offering a more adaptable and future-proof solution.

Another advantage of modular systems is their ease of maintenance. Because individual components can be swapped out without affecting the whole system, control integrators can minimize disruption during repairs or upgrades. This approach makes it easier for businesses to keep their automation systems running smoothly while still staying up-to-date with the latest technological advancements.

Optimizing Energy Management Through Intelligent Automation

Energy efficiency is becoming a top priority for industries looking to reduce their operational costs and minimize environmental impact. Control integrators are now focused on incorporating intelligent automation systems that can optimize energy usage without sacrificing performance. These systems use real-time data and smart algorithms to monitor energy consumption and make adjustments that reduce waste.

One of the key benefits of this trend is the ability to cut down on energy costs by automating energy-intensive processes. Control integrators design systems that can automatically switch off equipment when not in use or adjust energy consumption based on real-time demand. This not only helps businesses save money but also supports sustainability initiatives by reducing carbon footprints.